Problems/ dangers because of grease deposits in the extract air system:

Large amounts of fat particles rise with the thermal air flow caused by cooking, deep-frying and frying. A good portion of these fat particles is usually separated by mechanical aerosol separators, which are installed in exhaust hoods and ventilated ceilings. But even the best aerosol separators do not collect all fat particles.

This leads to fat deposits in extract air ducts and downstream equipment exhaust plant, if you have any concern about your catering equipment, we would like to hear them.

As a result, the risk of fire hazards in these areas increases. In addition, hygiene problems, for example, mould formation (due to nutrient-rich fat deposits), may occur.

Another problem may be unwanted odours in the kitchen. These do not only arise when deep-frying, cooking or frying but also from fat deposits inside the extract air ducts.

Conventional Cleaning:

Conventional cleaning involves complex and expensive cleaning at regular intervals using robots, high-pressure cleaners and high-performance chemicals to locate the fat deposits in the ducts and remove them. The conventional way of cleaning can, however, only solve the above mentioned problems in the short term and only partly. Many places in the duct system cannot be reached because, for example, of the lack of inspection hatches. The highly aggressive, high performance chemicals used for conventional cleaning also cause considerable problems especially for older duct systems.

Our solution:

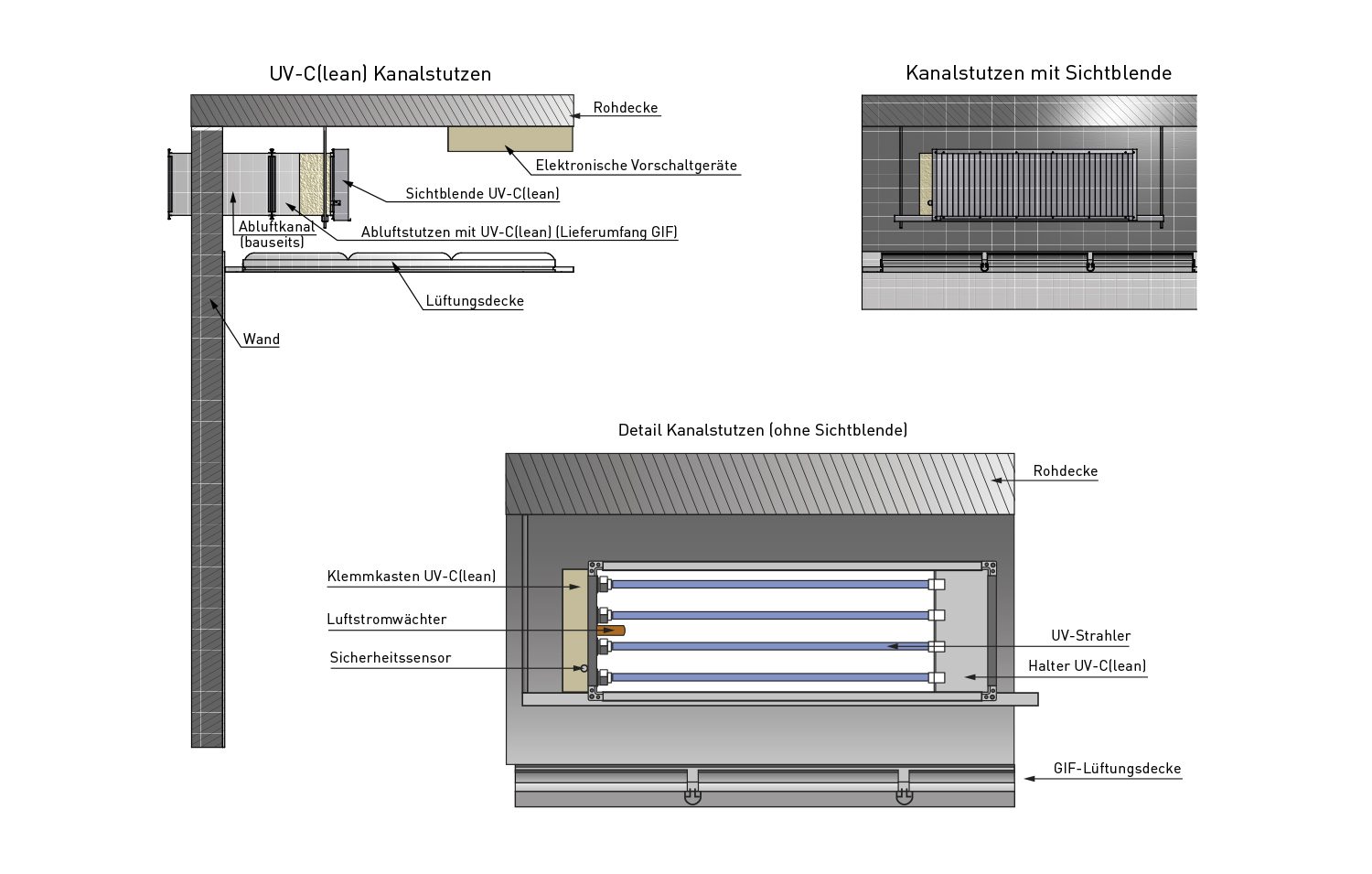

The GIF UV-C(lean) System is the ultimate solution for the decomposing of organic fats and oils in the kitchen extract air by means of UVC-light. Oils and fats are hydrocarbon compounds, the individual molecules of which consist of several carbon atoms, which are linked to one another by single or multiple bonds.

1. When greasy substances are irradiated with intensive UVC-radiation a part of the energy of the UVC-light is absorbed by the fat or oil. The fat molecules are brought into an energetically stimulated state which enables the fat molecules to be oxidised much more quickly.

2. At the same time, ozone is created by the action of the UVC-radiation on the oxygen molecules of the air. The oxidation capacity of ozone is much higher than that of the normal oxygen in the air. These two processes enable the fat molecules to be oxidised immediately (“cold combustion“). The products of the oxidation formed as a result are gaseous, short-chain, organic compounds (e.g. carbon dioxide), which are removed by the extract air stream.

- Reduced fire load in kitchen extract air equipment

- Reduced cleaning costs

- Improved hygiene

- Conforms to EN 16282-8

- Improved quality of air when using heat recovery equipment according to EnEV [German Energy Savings Regulation] 2014

- Several safety devices for personal protection networks

- Can also be installed as upgrade set for exhaust air hoods, duct nets, GIF Ventilated Ceilings and GIF Jet Stream Extractor

- Maximum efficiency combined with GIF Ventilated Ceilings

- Unique UV-Clean lamp operating time of 10,000 hours with a minimum loss of efficiency

- Hardly any fatty degeneration on the lamps as a result of high UVC performance per square centimetre

- Reduces odours

| Performance | 130 or 180 Watt per UV-lamp Usage according to individual requirements | |

| Function time / Service life of lamps | 10,000 hours | |

GIF ActiveVent GmbH

Since it was founded in 1976 GIF ActiveVent’s core area of expertise has been developing and producing individual modular ventilated ceilings and systems for use in different professional kitchens. In doing so, we have positioned ourselves at the head of the market.

Interesting Links

www.fcsi.org

www.hki-online.de

www.vdfnet.de

www.vkk-ev.de

Blog categories

All Information

Events

Jobs

References

News & Innovation

Important Keywords

Commercial kitchens

Ceiling solutions

Ventilated ceiling

Professional kitchens

Modular ventilated ceiling

Extraction Ceilings

ecoAZUR

Active Cassette Ceiling

Restaurant system

Supply Air

Flat Cassette

Ceiling

Lighting

Flat System Ceiling

Jet Stream

Extractor

UV-C(lean)

Headquarters

GIF ActiveVent GmbH

Brühlstraße 7

79112 Freiburg im Breisgau

Germany

Contact

Phone: +49 (0)7664 93020

Fax: +49 (0)7664 9302-43

E-Mail: info@gif-activevent.com